Highlights

- Library construction: built the front ducts, sound booth, etc.

- Render Cluster build. Case modifications.

- Purchasing.

- Tax preparation (Business Taxes).

- Python software contract (I18N, Python 3, GTK 3)

- Central Market Set development (“Lunatics!”, S1E01-TB sequence.

Video Summary

Summary of Correspondence

Most of the correspondence this month had to do with a software contract I was working to internationalize a Python program and bring it up to date with Python 3 and GTK3.

Selected Art

Photos

[EDIT: I screwed up dates. These photos (and therefore the construction) are from 2016. I had just downloaded the photos in January 2017. I’ll move this section to the appropriate month or months when I get to them. I thought it seemed like an amazingly productive month!]

Studio Library Construction

My office is built into the back 12-feet of an ocean storage container. The front had been used as a library until 2013, with a collection of old shelf sets we’d accumulated over the years, and a doorway that was really an interior door mounted in a frame with chipboard paneling.

However, this burned out in December 2013, and much of the library interior was damaged by heat, smoked, and the water used to put out the fire. From 2013 to 2017, the front of the building was just a burnt-out hole, so it was pretty hard to keep out the elements, and this didn’t do the contents any good, either.

This year, we could finally afford to remodel as we had originally planned since we bought the storage unit. The front opening has similar framing to the old front, except that now, a large glass-paneled french door is installed, with an acrylic transom window on top, and vents on the sides.

Inside, we installed full insulation, as we had done for the office, and then pinewood shelving, I built with a table saw I bought specifically for this project.

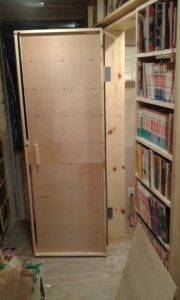

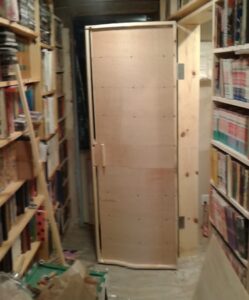

Sound Booth

I constructed a special, sound-insulated closet behind some of the bookcases (the books provide additional sound insulation). This was built to have a communicating vent into the office, through which the booth would get fresh, conditioned air, via a very quiet fan, and wires could be run for USB connection to record on my workstation.

Note that there are very few connections between the inner and outer wall support, with a layer of insulation in between. This reduces the transmission of sound vibrations from the outside into the booth. The room is also not rectangular, so that the walls do not set up a resonance between them (couldn’t do much about the floor-to-ceiling space, though I did tilt part of the ceiling space for this reason). This is to break-up internal sound reflection — of course, I would also install damping foam and carpeting.

I always wanted to build a bookcase door! The door isn’t really “hidden”. The hinges and doorknob are easy to see. But it is “unobtrusive”:

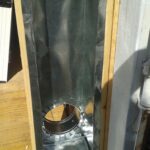

Ducting (Server Closet Ventilation)

Flexible duct installation:

I provided a diverter to allow hot air to be blown into the room in the winter, rather than exhausted outside. In retrospect, I’m not sure that was a good idea (it leaked too much, allowing hot air to vent inside in the Summer, reducing the air-conditioning efficiency. I wound up blocking it to prevent this).

Construction of soffit around the duct:

Air supply duct:

It was more practical to put the supply duct along the floor. I was a little concerned that I’d pick up more dust and pollen from outside this way, but it still seemed like the best option.

Front Ventilation Ports

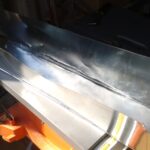

This was my first experience with sheet-metal fabrication and tools!

Installation of the ducts:

The ducts fan out a great deal at the front of the building, in the spaces to either side of the doorway. This is an ocean cargo container, with few structural alterations, so this is the main access for fresh air and means to vent hot air from the building. In the future, I might make alterations to improve this, but it requires cutting the thick corrugated steel of the container, which needs to be done with a blowtorch or a plasma cutter.